The solution of controlling pump station system using inverter and PLC via Profinet protocol

As we all know, pumps are a very useful device in industrial systems in general and in fluid transmission systems in particular, it is used for many different purposes depending on the application of each system. Typically, fuel pumping systems through tanks, cooling water pumping systems, etc

Pumping systems in the industry today are becoming more diverse and complex, so the installation and control of pumping systems are increasingly not easy. But the refilling system plays an important role and has a great influence on the operation of a large system and can cause loss of energy and resources if the pumping system is not well managed.

Recognizing the importance of the management of the pumping station system, SAI GON ELECTRIC CO.,LTD. has introduced solutions for systems using multiple pumping stations by using modern equipment and high management efficiency. And still saves installation and operating costs.

Purpose, requirements for the pump station system

Description:

- With the system as we saw above, the pump performs the task of taking water from the source to bring it to the place where it needs to be cooled. These pumping stations are distributed in a large space away from the factory, away from the control center, resulting in difficult operation monitoring.

- To improve the efficiency of the operation and monitoring of the above system, it is necessary to select an appropriate remote control and monitoring program for the above system.

Solution for pump station system

1. Introduction:

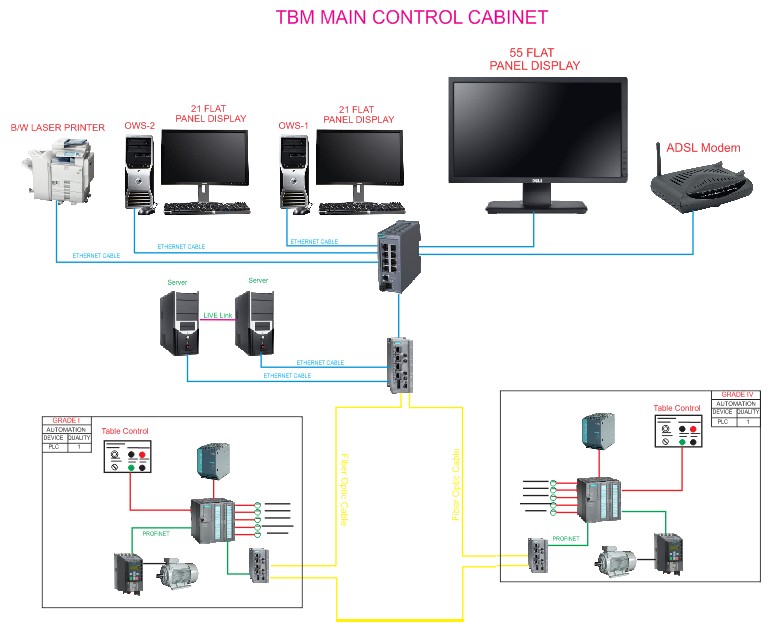

- In this system, each pump station will have a PLC controller to monitor and control the pumps through the control of inverters in the station, each water tank will be installed level sensors to indicate the level. country. behind the pipeline each pump will be a flow sensor and pressure sensor, all signals are transmitted to the PLC.

- At the center, a SCADA system will be built to remotely monitor and control the pumps through communication with the PLCs..

- These PLC units have a built-in Profinet port (a communication standard for industrial Ethernet), and the selected drives also have a built-in communication protocol, resulting in synchronization in communication. Everything is more accessible.

2. Controllers at each pump station:

Each inverter will control the operation of each pump through SCADA station sending messages via PLC. Advantages of applying the inverter to the control of pump operation :

- Speed control according to the set value

- Fast response, high accuracy

- Reduce energy consumption (this is the biggest advantage of using variable tons)

- Support communication protocol for remote control easily

- Extend equipment life.

3. Communication solutions of the system:

Each inverter will control the operation of each pump through SCADA station sending messages via PLC. Advantages of applying the inverter to the control of pump operation:

- Each inverter will control one pump.

- The drives will be connected to the PLC, the PLCs will connect to the SCADA system at the central control room.

- Profinet communication protocol control system.

4. PLC controller:

- Monitor and control the entire pump station according to different operating modes.

- Connect and control the inverter.

- Monitor measurement values: pressure, flow, water level, voltage, current, power consumption.

- Status monitoring: ON / OFF / TRIP, Runtime.

- Integrated Profinet communication

Power management Systems

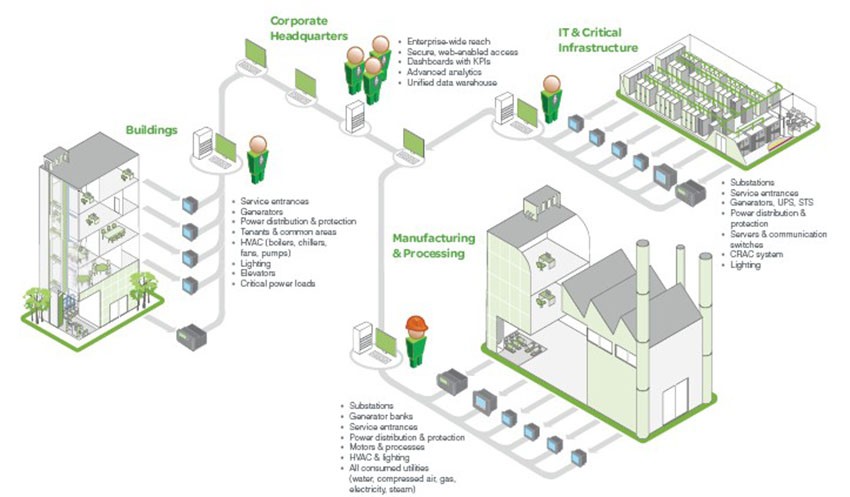

Today, with the development of the 4.0 industrial revolution, Vietnam has begun to appear many automatic control systems for energy monitoring, but the integration is not high. Most of these systems are often used for large applications, so the cost is relatively high, not suitable for many small factories and enterprises. Therefore, the study of designing a monitoring and data collection control system to manage and monitor energy in factories and enterprises in Vietnam is practical and necessary work.

SAI GON ELECTRIC CO.,LTD has been seeking to provide the most optimal solution for building an energy management system. This system not only helps customers to minimize implementation costs but still ensure high efficiency, but also provides customers with a convenient operating process with an intuitive interface, vivid and simple operation.

As an official partner of Siemens Group – a leading group in providing automation equipment and solutions, SAI GON ELECTRIC CO.,LTD uses most of Siemens equipment with high quality and always ensure safety for customers during use. The energy management system provided by our company always ensures the honesty about the equipment and price, always offers good solutions for each different requirements of customers, and always consult and support maximum customers to create products that meet general requirements.

Describe system overview

Cost-effective software monitoring interface.

1. Overall interface:

2. Parameter Monitoring:

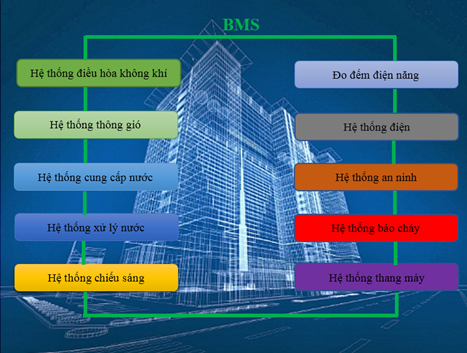

1. Introduction of Building Management System (BMS)

Building management system (BMS) is a comprehensive system for controlling and monitoring all technical systems, various electrical and mechanical equipment in the building. The investors’ solution requirements are fully met with automatic control features to each mechanical-electrical system in the building:

- Air conditioning system

- Building ventilation system

- Power system

- Water supply system

- Waste water treatment system

- Environmental warning system

- Security system, fire alarm

- Elevator system

- Lighting systems …

The integration of BMS system brings a modern solution, contributing to energy saving solutions in the building, ensuring the operation of equipment in the whole house is timely accurate.

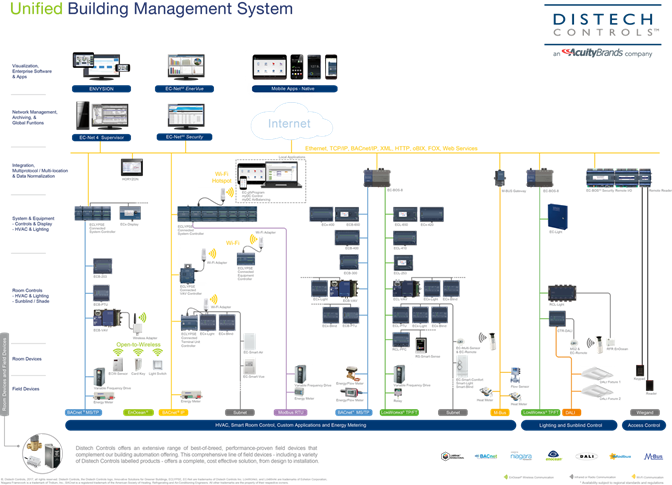

2. Function of BMS systems

Building management system allows:

- Intervene and automatically control all energy consumption systems to each location, each area of the building as required by the building manager and the customer.

- Allows connecting different technical systems such as security, fire alarm, elevator … into the same system, easy to control all technical infrastructure in the building.

- Monitoring air environment, working environment in the building. Improve service quality in the building.

- Allowing to intervene and automatically control all mechanical-electrical systems of the building according to schedule or in case of incidents.

- Automatically generates warning signals when there is a problem.

- Control the operation status of electrical and mechanical devices in the building such as: fan, air conditioner.

- Manage and provide complete information about power consumption.

- Provide periodic reports on demand, database management, data storage and backup

Depending on the purpose of the building, the BMS system will be equipped to an appropriate level.

3. Model of a BMS

4. Benefits and necessities of BMS system

Automation today is widely applied not only in particular manufacturing factories, specialized fields, but also increasingly applied to all areas of daily life. Along with that trend, many hotels, hospitals, buildings and office buildings have applied automated technology to infrastructure, helping to improve the ability to monitor and control management on each device and every infrastructure. technical in the system.

A BMS system concentrates every single infrastructure and system into a centralized system. In this system, people play a role in setting requirements, complying with requirements, performing operations undertaken by specific technical systems.

The intelligent control systems, automation in general and the whole house management system (BMS) in particular are increasingly widely used, in the future these systems will be increasingly applied more widely by the benefits and values that it brings:

Firstly, BMS helps improve automation, accuracy, and equipment in automatic and intelligent operation system. The equipment in the system is managed, controlled, optimized operation cycle under the control of BMS control system, helping to improve accuracy, contributing to reduce energy consumption and increase life expectancy. of setting through automatic calculation of parameters to make reasonable control decisions appropriate circumstances.

Second: BMS helps to liberate human labor. The BMS system automatically operates according to a preset schedule, records events, data, transmits alerts, helps reduce human intervention and monitoring into the system, the process of finding prizes. The decision to resolve the problem more quickly, the implementation of the report is also shortened.

Third: BMS brings convenience, improve system utilization performance. BMS provides a close, user-friendly interface through graphical interfaces that simulate the operation of devices in the system. Operators easily monitor all technical specifications, operating status of devices, security status anywhere in the central room, making it easy to make timely decisions and reactions.

Fourth: BMS helps support equipment maintenance. By providing warnings, recording incidents during operation, the BMS system makes it easy for operators to detect incidents in the system, contributing to faster maintenance.

Fifth: BMS brings unity in the system. Individual systems are unified in the same system, enabling different systems to interact with each other to provide appropriate controls in different situations.

Sixth: BMS helps improve energy efficiency, contributing to energy saving of the system. BMS monitors daily energy usage, automatically controls toggle on and off scheduled devices, precisely controls the load according to demand, optimizes response during system operation, contributes to reducing energy loss, bringing about high economic efficiency.

Related services

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt. Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur?

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga. Et harum quidem rerum facilis est et expedita distinctio. Nam libero tempore, cum soluta nobis est eligendi optio cumque nihil impedit quo minus id quod maxime placeat facere possimus, omnis voluptas assumenda est, omnis dolor repellendus. Temporibus autem quibusdam et aut officiis debitis aut rerum necessitatibus saepe eveniet ut et voluptates repudiandae sint et molestiae non recusandae. Itaque earum rerum hic tenetur a sapiente delectus, ut aut reiciendis voluptatibus maiores alias consequatur aut perferendis doloribus asperiores repellat.